General information

RDP Priority

- P1. Knowledge transfer and innovation

RDP Focus Area

- 1B: Links with research & innovation

RDP Measure

- M16: Cooperation

Beneficiary type

- Operational group

Summary

The province of Trento, in the North of Italy, close to the Austrian border, is a land of mountains and valleys, where forest and pastures cover approx. 89% of the territory. In the lower parts, vineyards alternate with orchards. Most farm owners of the province own a large amount of woodland as part of their estate, which is traditionally used for firewood or for furniture making. The farmers’ association Coldiretti also occasionally engages with representatives of research centres and technical assistance units. During such a meeting, a debate started on how to re-use cellulose derived from wood processing in line with the circular economy approach. The idea of producing innovative packaging and various other accessories was created and the five partner organisations formed an EIP Operational Group to assess the feasibility of these new products as part of an RDP project.

Results

- Laboratory tests confirmed the technical feasibility of producing various PLA (polylaminate) materials/prototypes from the cellulose of the local conifers’ wood.

- Tests with cellulose thread confirmed the suitability of PLA, in terms of durability and resistance, to be used for a range of agricultural purposes and tasks.

- Feedback from local SMEs showed that 40% were willing to use the new PLA material if available. In addition, 70% of the surveyed consumers were also in favour of the new wood-derived packaging material.

- The 'idea competition' produced various new ideas with potential for the use of PLA.

Funding

Total budget: 402 840 (EUR)

EAFRD: 138 513 (EUR)

National/regional: 183 759 (EUR)

Private/own: 80 568 (EUR)

Context

The province of Trento, in the North of Italy, close to the Austrian border, is a land of mountains and valleys, where forest and pastures cover approximately 89% of the territory. In the lower parts, vineyards alternate with orchards (mainly apples and pears). Most farm owners in the province own a large amount of woodland as part of their estate, which is traditionally used for firewood or for furniture making. The main farmers’ association (Coldiretti) is active in the area and, when attending fairs, it also engages occasionally with representatives of research centres and technical assistance units. During such a meeting, a debate started on how to re-use cellulose derived from wood processing in line with the circular economy approach. The idea of producing innovative packaging and various other accessories was created and the five partner organisations involved in the debate, namely Coldiretti Trentino, Codipra, Agriduemila srl, PEFC Italia and the scientific partner CNR-Ivalsa, considered assessing the feasibility of these new products as part of an RDP project.

Objectives

The main aim of the EIP project was to test the technical feasibility of using cellulose from wood waste as a new material for producing various products to replace other materials (e.g. plastics). The wood waste would originate from the local forests in Trento that are certified, sustainably managed forests according to the PEFC quality standard. From a wider perspective, the project also aimed at finding new ways to connect agriculture sectors with forestry sectors at the provincial and regional scale.

Activities

The main activities of the EIP Operational Group TAF/17 (‘Trentino-Agriculture-Forestry’, designed in 2017) included the following:

- Carrying out tests in a laboratory to investigate the technical feasibility of using cellulose from local conifers’ wood to produce a thin polylaminate (PLA) and to mix it with other bio-tissues (derived from crops such as corn for example) for further uses.

- Organising an 'idea competition' among the students at the University of Trento for finding new potential uses for the new base material.

- Undertaking an economic assessment of the production cost of the new material.

- Gathering feedback from SMEs of the local agro-food value chain, and from consumers of fruits and vegetables.

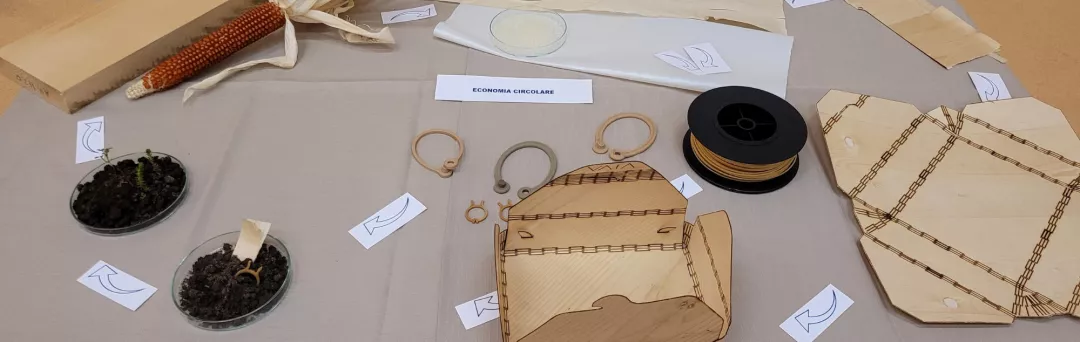

- Piloting the use of the newly developed materials in practice.

- Carrying out various awareness raising and dissemination activities at local fairs and round table events, presenting the project’s key topics.

Main results

- The laboratory tests confirmed the technical feasibility of producing various PLA (polylaminate) materials/prototypes from the cellulose of the local conifers’ wood while complying with current safety and hygiene standards (e.g. for packaging fruit and vegetables).

- The 'idea competition' produced various new ideas with potential for the use of PLA (e.g. wood cards for hotel check-in tasks).

- The economic assessment of the new products showed that no significant difference existed in terms of the price of the production of PLA in comparison to other more common packaging materials.

- Feedback from local SMEs (apple and vegetable producers and processors) showed that 40% were willing to use the new PLA material if available. In addition, 70% of the surveyed consumers were also in favour of the new wood-derived packaging material.

- Tests with cellulose thread (to tie plant branches with) confirmed the suitability of PLA, in terms of durability and resistance, to be used for agricultural purposes and a range of tasks.

- The interest expressed by participants of the awareness raising and dissemination activities was positive.

Key lessons

- Unfortunately, after the project was completed, the partnership could not find a local factory willing to produce the material at an industrial scale - the outbreak of the COVID-19 pandemic did not help in this regard.

- It was rewarding that the envisaged idea of an opportunity was turned into a reality: it was confirmed that wood waste can be used as a new packaging material replacing plastics.

“Working in partnership with a rather diversified set of subjects proved very stimulating and rewarding for everybody in the Operative Group.”

EIP Operational Group participant

Riccardo Soliani